Compared with the traditional concrete structure building system, the light steel structure engineering has the characteristics of large span, low structural requirements, strong earthquake resistance and wind resistance, beautiful appearance, short construction period, strong corrosion resistance, no pollution, low maintenance cost. Therefore, it is increasingly favored by consumers. Mainly used in long-span structure, factory, warehouse, office building, large supermarket, logistics warehouse, showroom, hangar and so on.

Due to the diversification of steel structure materials and flexible design, light steel structure engineering can better meet the needs of customers for space structure, reasonable economy.

Company Profile

Company Profile

Established in 1997,Qingdao Xinguangzheng Steel Structure Co., Ltd is a large-scale professional manufacturer specializing in designing, modeling, manufacturing and installing Steel Structure Projects.

Advanced equipment, great production capacity and prompt delivery that make us establish good relationship with more than 90 countries and regions:Canada,The United States,UAE,South Africa,Germany,France,Japan,Argentina,Venezuela and many other countries and regions. And we have participated in many significant construction projects, such as Argentine Workshop, Australian Aircraft Hanger, Mauritius Government Projects and so on.

The company tenet of us is to "perfect itself and create wealth by taking the social development as its responsibility;the enterprise,a platform;and its team, the core of development".

Building system

1. Strong steel structure frame, strong, windproof, snow proof, earthquake proof.

2. Plastic steel is steel warehouse material, easy to design, warehouse space, light weight.

3. Sandwich board and color steel plate as maintenance system, heat insulation, beautiful, waterproof, sound insulation.

4. Bolt connecting steel bar workshop, easy installation and disassembly.

5. Cold formed steel gutter and downspout are good for drainage system.

We can design our own, to provide you with the most suitable solution.

One-stop service from design, manufacturing, delivery to installation and after-sales service.

We can strictly follow your drawings and requirements for production.

Our Advantage & Service

1)Rich experience and professional team

With more than 20 years' experience, our employees have been professionally trained and evaluated , we can manufacture strictly according to your drawings and request or design by ourselves to provide you a most satisfactory solution to you.

2)Advanced equipment

We also have possessed more than 80 sets of large precise and domestically advanced processing equipment, including large gantry planning machines, automatic submerged arc welding machines, assembling machines, slitters, shot blasting machines and so on.

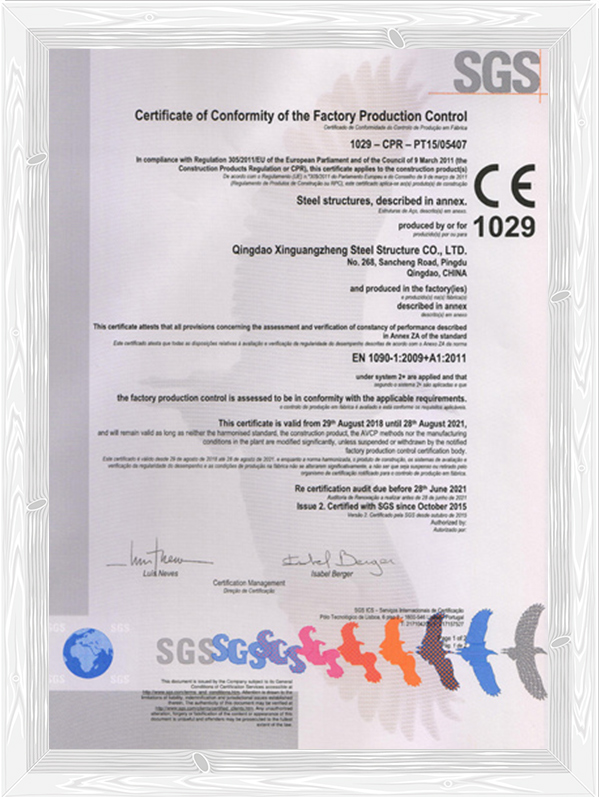

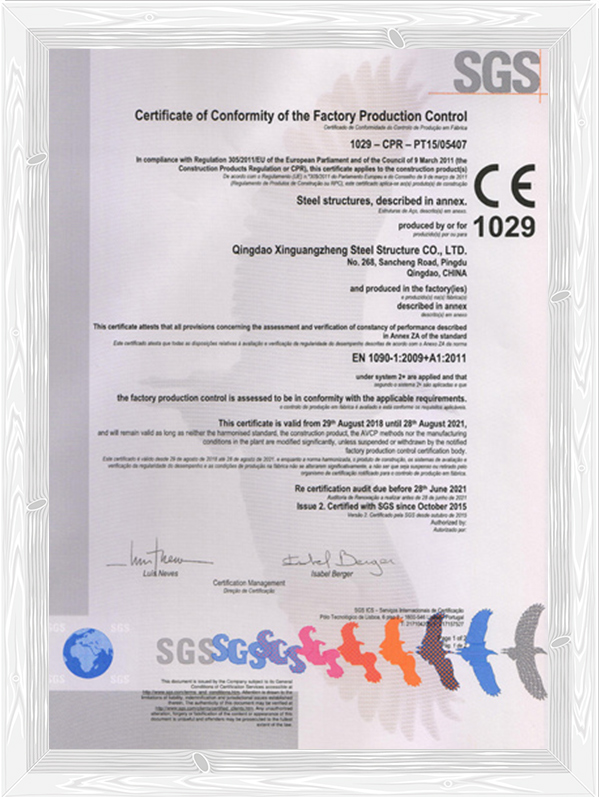

3)Strictly quality control, Inspection every production link

There are 2-3 quality inspection personnel in each of our workshop to carry out the product inspection and reinspection

4)Preinstall before delivery

We test assembling after assembling the first batch products, and then batch assembly if they're qualified

5)Prompt Delivery

Within 25-60 days after the order confirmed, also depends on the fabrication quantity.

Overseas project presentation

Compared with the traditional concrete structure building system, the light steel structure engineering has the characteristics of large span, low structural requirements, strong earthquake resistance and wind resistance, beautiful appearance, short construction period, strong corrosion resistance, no pollution, low maintenance cost. Therefore, it is increasingly favored by consumers. Mainly used in long-span structure, factory, warehouse, office building, large supermarket, logistics warehouse, showroom, hangar and so on.

Due to the diversification of steel structure materials and flexible design, light steel structure engineering can better meet the needs of customers for space structure, reasonable economy.

Company Profile

Company Profile

Established in 1997,Qingdao Xinguangzheng Steel Structure Co., Ltd is a large-scale professional manufacturer specializing in designing, modeling, manufacturing and installing Steel Structure Projects.

Advanced equipment, great production capacity and prompt delivery that make us establish good relationship with more than 90 countries and regions:Canada,The United States,UAE,South Africa,Germany,France,Japan,Argentina,Venezuela and many other countries and regions. And we have participated in many significant construction projects, such as Argentine Workshop, Australian Aircraft Hanger, Mauritius Government Projects and so on.

The company tenet of us is to "perfect itself and create wealth by taking the social development as its responsibility;the enterprise,a platform;and its team, the core of development".

Building system

1. Strong steel structure frame, strong, windproof, snow proof, earthquake proof.

2. Plastic steel is steel warehouse material, easy to design, warehouse space, light weight.

3. Sandwich board and color steel plate as maintenance system, heat insulation, beautiful, waterproof, sound insulation.

4. Bolt connecting steel bar workshop, easy installation and disassembly.

5. Cold formed steel gutter and downspout are good for drainage system.

We can design our own, to provide you with the most suitable solution.

One-stop service from design, manufacturing, delivery to installation and after-sales service.

We can strictly follow your drawings and requirements for production.

Our Advantage & Service

1)Rich experience and professional team

With more than 20 years' experience, our employees have been professionally trained and evaluated , we can manufacture strictly according to your drawings and request or design by ourselves to provide you a most satisfactory solution to you.

2)Advanced equipment

We also have possessed more than 80 sets of large precise and domestically advanced processing equipment, including large gantry planning machines, automatic submerged arc welding machines, assembling machines, slitters, shot blasting machines and so on.

3)Strictly quality control, Inspection every production link

There are 2-3 quality inspection personnel in each of our workshop to carry out the product inspection and reinspection

4)Preinstall before delivery

We test assembling after assembling the first batch products, and then batch assembly if they're qualified

5)Prompt Delivery

Within 25-60 days after the order confirmed, also depends on the fabrication quantity.

Overseas project presentation